Introduction

Fabric tensile strength is a critical property that determines the durability, performance, and quality of textiles in various industries, including apparel, automotive, aerospace, and medical applications. Measuring this property accurately requires specialized equipment known as Material Testing Machines. These machines play a pivotal role in ensuring that fabrics meet industry standards and perform as expected under stress.

This article explores the importance of fabric tensile strength, the principles behind tensile testing, and how Material Testing Machines facilitate precise and reliable measurements. We will also discuss different types of tensile tests, industry standards, and advancements in testing technology.

Understanding Fabric Tensile Strength

What Is Tensile Strength?

Tensile strength refers to the maximum amount of tensile (pulling) stress a fabric can withstand before breaking or deforming. It is a key indicator of a material’s mechanical properties and is measured in force per unit area (e.g., Newtons per square millimeter or pounds per square inch).

Why Is Tensile Strength Important?

Durability & Performance – Fabrics with high tensile strength resist tearing and stretching, making them suitable for heavy-duty applications like industrial workwear and military gear.

Quality Control – Manufacturers test tensile strength to ensure consistency in production and compliance with industry regulations.

Safety & Reliability – In applications such as parachutes, seatbelts, and medical implants, tensile strength directly impacts safety.

Material Selection – Engineers and designers rely on tensile strength data to choose the right fabric for specific applications

The Role of Material Testing Machines in Tensile Strength Measurement

How Do Material Testing Machines Work?

A Material Testing Machine (also known as a universal testing machine or tensile tester) applies controlled tension to a fabric sample until it fails. The machine records the force applied and the elongation of the material, generating a stress-strain curve that helps determine:

Ultimate Tensile Strength (UTS) – The maximum stress a fabric can endure.

Yield Strength – The point at which the fabric begins to deform permanently.

Elongation at Break – How much the fabric stretches before breaking.

Modulus of Elasticity – The stiffness of the fabric.

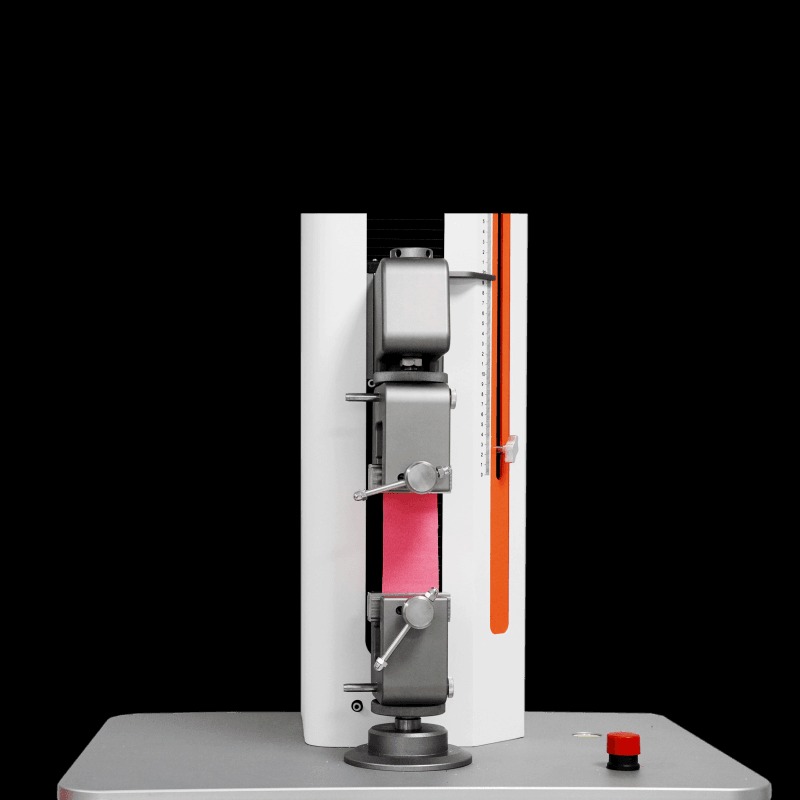

Key Components of a Material Testing Machine

Load Frame – Provides structural support for the test.

Load Cell – Measures the force applied to the fabric.

Grips & Fixtures – Hold the fabric sample securely during testing.

Extensometer – Measures elongation accurately.

Software & Data Acquisition System – Records and analyzes test results.

Types of Tensile Tests for Fabrics

Strip Test – A rectangular fabric sample is clamped and pulled until it breaks.

Grab Test – Only a portion of the fabric width is gripped, simulating real-world stress conditions.

Tear Test – Measures resistance to tearing (e.g., Elmendorf tear tester).

Burst Strength Test – Evaluates a fabric’s ability to withstand pressure (common in medical and industrial textiles).

Industry Standards for Fabric Tensile Testing

To ensure consistency, various organizations have established testing standards, including:

ASTM D5034 – Standard test method for breaking force and elongation of textile fabrics (strip test).

ASTM D5035 – Standard test method for breaking force and elongation of textile fabrics (grab test).

ISO 13934-1 – Determination of maximum force and elongation at maximum force using the strip method.

EN ISO 13937-2 – Tear properties of fabrics using the trapezoid method.

Adhering to these standards ensures that test results are comparable across different laboratories and industries.

Advancements in Material Testing Technology

Modern Material Testing Machines incorporate advanced features for higher precision and efficiency:

Automated Testing – Reduces human error and speeds up repetitive tests.

Real-Time Data Analysis – Software provides instant stress-strain graphs and statistical reports.

Multi-Functional Testing – Some machines can perform tensile, compression, and bending tests.

Environmental Chambers – Allow testing under controlled temperature and humidity conditions.

Non-Contact Extensometers – Use optical sensors for highly accurate elongation measurements without touching the sample.

Applications of Tensile Testing in Different Industries

1. Apparel & Fashion

Ensures fabrics can withstand everyday wear and washing.

Tests stretchability in activewear and denim.

2. Automotive & Aerospace

Evaluates seatbelt webbing, airbag fabrics, and composite materials.

Ensures materials meet safety regulations.

3. Medical Textiles

Tests surgical mesh, bandages, and implantable fabrics for strength and biocompatibility.

4. Industrial & Protective Gear

Assesses durability in fire-resistant suits, conveyor belts, and geotextiles.

Challenges in Fabric Tensile Testing

Despite advancements, some challenges remain:

Sample Preparation – Inconsistent cutting or clamping can affect results.

Anisotropy – Fabrics may have different strengths along the warp and weft directions.

Environmental Factors – Humidity and temperature can influence fabric behavior.

Proper calibration and adherence to standardized procedures help mitigate these issues.

Conclusion

Fabric tensile strength is a fundamental property that influences the performance and safety of textiles across multiple industries. Material Testing Machines provide the precision and reliability needed to assess this property accurately, ensuring compliance with international standards.

As technology advances, these machines continue to evolve, offering faster, more automated, and highly accurate testing solutions. Whether in fashion, automotive, medical, or industrial applications, understanding and measuring tensile strength remains essential for producing high-quality, durable fabrics.

By leveraging advanced Material Testing Machines, manufacturers and researchers can push the boundaries of textile innovation while maintaining the highest standards of quality and safety.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@tes.hk