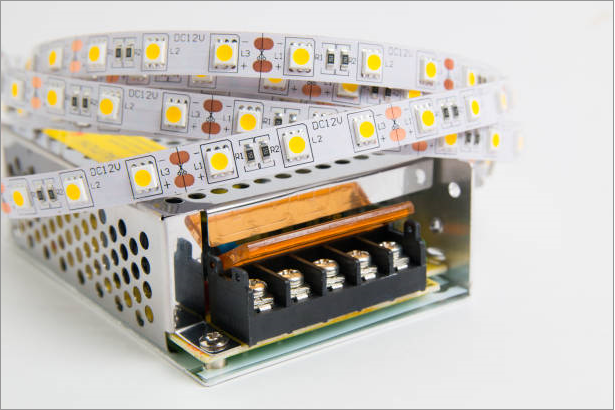

When it comes to building a lighting business that lasts, there’s one component that’s often underestimated: the power supply. Sure, we all obsess over design, brightness, color temperature, and smart features—but none of that matters if your LEDs don’t have the right power behind them.

That’s where choosing the right LED power supply manufacturer comes into play. Whether you’re an installer, a lighting retailer, a contractor, or someone scaling a lighting brand, your choice of manufacturer will significantly impact your quality, reliability, and long-term success.

First, let’s fix this important line so it reads correctly:

LED Power Supply Manufacture refers to the process and expertise involved in designing and producing the power sources that enable LED lighting systems to function efficiently and safely.

If you’re in this business for the long haul, choosing the right manufacturing partner isn’t just a smart decision—it’s a strategic one. Let’s explore how to find a reliable LED power supply manufacturer that you can count on for the long term.

Why the Manufacturer Matters More Than You Think

Let’s face it: LEDs are only as good as their weakest component—and too often, that’s the power supply. A poor-quality driver can cause:

Flickering lights

Voltage spikes

Early burnout

Heat issues

Inconsistent performance

Worse still? A failed power supply affects not just your products, but also your reputation, warranty costs, and customer satisfaction.

Reliable LED Power Supply Manufacture ensures that your products deliver performance day after day, for years—not just weeks.

1. Look for Engineering-Driven Companies, Not Just Resellers

Not all “manufacturers” are created equal. Some claim to be manufacturers but actually just rebrand or distribute other companies’ products. What you need is a true manufacturer with:

In-house R&D capabilities

Testing labs and quality control departments

Custom design support (if needed)

A proven history of innovation

Ask yourself: Can they explain how their power supply protects against surges? Can they modify voltage or dimming capabilities based on your needs? If yes, you’re talking to the real deal.

2. Check for Essential Certifications

A good manufacturer doesn’t just claim quality—they prove it.

At a minimum, their products should comply with:

UL or ETL (for North America)

CE and RoHS (for Europe)

FCC (for electromagnetic compliance)

ISO 9001 (quality management system)

These certifications signal that the manufacturer takes safety and quality seriously—and that their products meet the standards required in most global markets.

3. Evaluate Their Product Range

A reliable manufacturer offers a diverse catalog to serve a wide variety of projects, including:

Constant voltage power supplies (12V, 24V, 48V)

Constant current drivers

Dimmable options (TRIAC, 0-10V, DALI, PWM)

Waterproof/IP67-rated units for outdoor use

Slim and low-profile drivers for architectural projects

Smart compatible supplies for IoT systems

Even if you don’t need all these now, you might down the road. A diverse lineup shows manufacturing depth—and future-proof flexibility.

4. Ask About Warranty and Support

Let’s be honest: even great products sometimes fail. That’s why a reliable manufacturer will offer:

Transparent warranty policies (at least 3–5 years)

Real after-sales support via phone, email, or chat

Fast RMA or replacement processes

Technical documentation, including datasheets and installation guides

Support isn’t just a bonus—it’s a core part of the package when you’re choosing someone for long-term collaboration.

5. Transparency in Pricing and MOQ

When sourcing from manufacturers, you should expect:

Volume-based pricing

Clear minimum order quantities (MOQs)

No hidden fees

Quote breakdowns by model or custom spec

A trustworthy manufacturer will be up front with costs. If they’re evasive or pushy, walk away.

6. Communication Is Everything

This one’s easy to overlook, but so critical. How responsive is the manufacturer?

Do they answer emails within 24–48 hours?

Are they comfortable with English (or your preferred language)?

Can they jump on a call or video meeting if needed?

Do they confirm orders and update shipping timelines clearly?

Great communication often equals great reliability, especially when projects are on the line.

7. Consider Their Manufacturing Capacity

If you’re growing—or plan to—it’s essential your manufacturer can grow with you.

Ask:

How many units can they produce per month?

Do they have automation or scaling systems in place?

Can they handle rush orders or seasonal demand spikes?

Do they operate their own factory or outsource production?

Long-term success means consistency, and that can only happen if the manufacturer has the capacity to deliver.

8. Test First—Always

Before you commit to large orders, ask for:

Samples of various models

Datasheets and product documentation

Test results or lab certifications

Run those supplies through your systems. Check for voltage stability, heat management, noise, and dimming accuracy. Don’t skip this step—real testing reveals real quality.

9. Reputation and References

If they’ve been around for a while, chances are they have a trail of happy (or unhappy) customers behind them.

Check LinkedIn for company updates and presence

Look for reviews on B2B marketplaces (Alibaba, Made-in-China, Global Sources)

Ask directly for customer references or case studies

Search forums like Reddit or electrical contractor groups

You’ll learn a lot from others who’ve walked this road before you.

10. Location Isn’t Everything—but It Does Matter

Many top manufacturers are based in Asia (especially China and Taiwan). That’s not a bad thing—some of the most reliable brands in the world operate there.

But consider:

Shipping times and costs

Local regulations (if importing

Time zone communication lag

Language barriers

If you can find a supplier with a local distributor or warehouse, it can speed up logistics and give you peace of mind.

FAQs About LED Power Supply Manufacture

Q1: What’s the difference between a manufacturer and a supplier?

A manufacturer makes the product—handles the design, assembly, and testing. A supplier might resell it. If you’re after long-term control and consistency, go straight to the manufacturer.

Q2: How do I know if an LED power supply is high quality?

Check for certifications (UL, CE), look for high efficiency (>85%), stable output under load, low heat emission, and strong warranty coverage.

Q3: Are OEM or custom options available from manufacturers?

Yes, many offer OEM (your branding) or ODM (custom design) solutions. This is perfect if you’re building a branded lighting product line or targeting a niche market.

Q4: Should I be concerned about warranty enforcement with overseas manufacturers?

Yes and no. Trusted manufacturers honor warranties. However, ensure you have written agreements, understand their RMA process, and ideally have a local partner to help manage support.

Q5: What’s a typical lead time from order to delivery?

It depends, but most overseas manufacturers ship within 15–30 days for standard orders. Custom orders may take longer. Confirm timelines before placing high-volume orders.

Conclusion: Think Long-Term, Choose Smart

Finding a reliable LED power supply manufacturer isn’t about scoring the lowest price—it’s about investing in a partner who helps you grow, protects your reputation, and delivers quality consistently.By focusing on technical expertise, certifications, support, and communication, you can build a supply chain that doesn’t just work—but works for years.LED Power Supply Manufacture isn’t a commodity. It’s a craft. And when you find a manufacturer who treats it that way, your lighting business becomes stronger, more trusted, and ready for whatever comes next.